Final April, I launched you to a seemingly game-changing new 3D printer: the AnkerMake M5. “Printing So Good, It’s Simple”, the corporate’s tagline learn.

3D printing has by no means been precisely what I’d name “straightforward,” however Anker actually turned my head with its multi-part pitch:

- Prints 5 instances sooner than the competitors so that you aren’t ready round

- A sturdy construct for easy, quiet, high-quality printing regardless of that velocity

- Three-step setup so that you’re printing simply quarter-hour “from the time M5 arrives at your door”

- An “AI digital camera” to avoid wasting you in case your print fails and ensure it “comes out precisely to your specs”

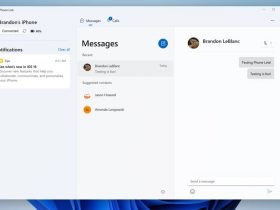

- Distant management, notifications, and HD viewing over the web

- Computerized timelapse movies you’d wish to share to social media

One yr later, how did Anker do? Personally, I’m experiencing an terrible lot of whiplash.

The Good

- Simple to assemble

- Genuinely prints quick

- Accepts various plastic varieties with ease

- Auto-leveling works as of an replace

The Dangerous

- AI digital camera is a joke

- Vibrations present up on prints

- Loud, even when idle

- Anker appears to have high quality management points

I’ve now spent a number of months with two AnkerMake M5 printers, burning by a number of spools of filament to provide dozens of components, and I wish to be clear: you possibly can genuinely get first rate practical components out of an AnkerMake M5, at remarkably quick speeds, even in the event you’re a 3D printing newbie.

Not too long ago, I nailed the hilt of a Legend of Zelda sword and a print-in-place tank with transferring treads on my very first attempt. I made a bouncing ball out of TPU and printed see-through shapes out of clear PETG with out having to tweak a single setting — I merely dropped a mannequin into the corporate’s PC software program, picked the fitting filament in “Simple” mode, and waited for a smartphone notification to let me know my print was executed.

Nevertheless it took me a lot longer than quarter-hour to get that far. Certain, that was sufficient time to assemble the printer’s core elements, but it surely took longer earlier than I noticed Anker didn’t correctly tighten the belts (and grossly overtightened the wheels and a few screws) earlier than the printer arrived at my door. Neither Anker’s printed directions or the LCD display screen instructed me something about fixing these points, and even easy methods to correctly load filament. (Anker’s head of selling instructed me a yr in the past that the printer would supply one-button filament loading; the function nonetheless doesn’t exist.)

Then, I needed to wait months for Anker to repair the printer’s firmware, which refused to correctly auto-level the mattress, would overlook key parameters whenever you shut it down for the night, scraped prints with its nozzle and left unusual cavities and lumps on each single print I attempted. That’s largely mounted as of a March replace — I can now cowl the complete mattress with a single sheet of skinny plastic of largely uniform consistency. (3D prints reside or die on their first layer, so that you at all times wish to get off on the fitting foot.)

However the high quality, at the very least with my overview items, nonetheless isn’t what Anker promised.

Above, you’ll see footage of a case I printed for my DJI Mini 2 drone three alternative ways: on the prime is one I printed on my previous Ender 3 Professional at 50 millimeters per second, then one on the AnkerMake M5 slowed all the way down to the identical 50mm/s, and eventually one on the AnkerMake M5’s 250mm/s default velocity on the underside.

You don’t must zoom in a lot to see that my previous Ender 3 Professional did a greater job, with good clear strains all the best way up. The AnkerMake floor simply doesn’t have that easy consistency the corporate promised, no matter whether or not I velocity the printer up or sluggish it down, tighten my belts and wheels, and even regulate the Z-block stress. The 3D printing neighborhood calls these strains “ringing” or “ghosting,” and it’s sometimes blamed on a printer’s high-speed vibrations affecting the print high quality. I see this impact on virtually each half I’ve tried, and I’m not the one one.

In virtually each different means, the AnkerMake’s print high quality is sweet! I actually like my Legend of Zelda sword, and I used to be impressed by the M5’s outcomes on the Autodesk Kickstarter Geometry Check; it’s a bit weak at overhangs, however with good bridging, dimensional accuracy, and only a few extra strings of plastic spiderweb hanging off its pointy little spires. But AnkerMake claims it acquired a 25.5/30 on that take a look at with an ideal rating on vibration, and that’s not what I noticed: my printers solely managed a 21/30 utilizing Anker’s personal pre-sliced mannequin and a brand-new roll of the required filament.

As you’d count on, these vibrations can worsen in the event you run the printer within the new “500mm/s” quick mode that Anker launched this month. Right here’s a pair 3DBenchys so you possibly can see what that appeared like for me:

Floor high quality isn’t the one disappointment. I used to be trying ahead to protecting this supposedly quiet printer in my home, however I rapidly needed to transfer it to the storage due to the fixed fan noise even when idle — to not point out how the printer inexplicably performs its homing maneuvers by noisily smacking its components round.

I additionally haven’t had a single timelapse video price sharing. Right here’s the promise vs. the fact:

Anker’s timelapse function isn’t sensible sufficient to do the naked minimal: It doesn’t even wait till the mattress is in the identical place earlier than snapping every shot, so what you see is a print jerking round. (It’d even be actual good if it briefly turned on the printer’s built-in mild, so you possibly can see the thing I’m printing is blue — not white.)

However for me, Anker’s greatest damaged promise is its “AI digital camera,” which has not labored even a single time in my months of testing.

Anker advertises that its digital camera ought to have the ability to detect three distinct forms of points:

- “Backside Layer Adhesion Failure” (when your print slips up and about)

- “Spaghetti Messes” (when your print turns right into a pile of plastic string)

- “Extruder Jam” (when filament stops popping out of the tip of the nozzle)

As a way to detect any of those, you presently want to make use of Anker’s personal slicer to create an AI mannequin that it supposedly passes alongside to the printer, so it will possibly — theoretically — continually verify whether or not the picture it’s getting from the digital camera appears to be like like the fitting form.

To place it mildly, the digital camera didn’t cease my prints once they slipped up and about, nor when items broke off mid-print. I actually printed spaghetti on objective and the digital camera didn’t detect it, to say nothing of the time a print by accident grew to become plastic pasta.

And of the 4 instances my filament stopped popping out of the extruder (certainly one of which was a jam; three of which have been as a result of the filament acquired caught on the reel, which sadly can’t journey a printer’s filament runout sensor), the AnkerMake M5 spent all 4 instances merrily printing nothing in the course of the air. The digital camera by no means observed something was flawed.

The one time error detection stopped my prints, it was for false positives, like when my black TPU ball’s first layer was maybe not what the digital camera anticipated. So it doesn’t shock me a bit that certainly one of Anker’s firmware updates turned off timelapse video and error detection by default.

And I might reside with that, however for one nagging worry — that due to some poorly designed or manufactured half or some new firmware replace, I’ll sooner or later get up to a printer that failed so catastrophically it’ll should be repaired.

I haven’t had that occur but, however there’s some purpose to fret. AnkerMake’s subreddit and Discord teams comprise quite a few horror photos of failed prints exploding right into a mushroom cloud of plastic that penetrates the complete print head, some proper as much as the circuit board. Whereas some have luck melting it off with cautious utility of a hair dryer, a number of discover the recent plastic has melted crucial elements and it’s time for a whole substitute extruder.

When prospects report {hardware} points, they attest within the AnkerMake Discord servers and subreddit, they’re typically anticipated to spend appreciable time proving the issue exists earlier than Anker agrees to ship them substitute components, which they then have to put in themselves.

Not everyone seems to be having big issues! I lurked in these AnkerMake communities for months, and I noticed loads of individuals say it’s printing like a dream. (Tom’s {Hardware} reviewer Denise Bertacchi, who exams 3D printers for a dwelling, gave this machine 4 stars.) However each Discord moderator I spoke to agreed: Anker has a top quality management difficulty. Not all machines are equal.

- Along with quite a lot of too-loose components and overtight wheels, some printers have shipped with broken V-wheels that merely don’t roll correctly.

- Others have points with screws: “The present hotend is held by two M2x16mm screws which can be identified to snap or break off extremely simply,” reads one part of the Unofficial AnkerMake Wiki (which additionally incorporates loads of sensible recommendation for anybody trying to troubleshoot this printer). You may wish to proactively change these in the event you purchase one.

- Personally, I can’t merely open up the extruder of certainly one of my printers to troubleshoot as a result of the manufacturing facility stripped a crucial screw. Others have reported comparable.

- Some imagine the “mushroom cloud” difficulty is a design flaw with the complete extruder, and an AnkerMake worker who goes by “Henry” appeared to agree, suggesting the corporate’s engaged on a redesign — solely to show round and counsel that prospects must pay for an eventual improve.

- Additionally, I ought to in all probability point out that the AnkerMake M5 doesn’t ship with an all-metal hotend as Anker promised throughout the Kickstarter marketing campaign; it has some plastic tubing inside.

I wasn’t capable of get Anker PR to meaningfully converse to any of those alleged points, or acknowledge the extruder in any respect. “The reviews I’ve obtained from our customer support workforce and product managers present the M5 {hardware} points are all inside regular tolerance ranges,” Anker world PR head Eric Villenes instructed me in February.

As an example, he prompt that the majority V-wheel points can largely be solved “by merely transferring the V-wheel forwards and backwards a number of instances” and that Anker will step in in the event that they’re really broken. He additionally stated Anker’s working to switch improperly put in USB-C cables on a case by case foundation. The one part with a identified difficulty: there was a batch of failing touchscreens that the corporate will change for any affected person.

In any other case, says Villenes, the corporate’s focus is on software program, and I do have to offer Anker some credit score there. In my first draft of this overview, I used to be prepared to jot down off the printer solely, giving it one of many lowest scores within the historical past of The Verge. Again then, each single certainly one of my prints had gaps and bulges, the machine couldn’t keep related to Wi-Fi, dripped filament the place it shouldn’t, the display screen often flipped the other way up, and the slicer was an utter mess. Issues have significantly improved since then, the corporate’s added must-have options like Vase Mode and the power to pause a print through Gcode (to, say, change filament colours), and I’m lastly getting a bunch of prints I like.

I simply hope it’ll solely get higher from right here on out, as a result of Anker isn’t executed altering issues up. In late February, it introduced it plans to change its complete printer slicer software program over to PrusaSlicer, and a few firmware updates have damaged issues at the same time as they’ve mounted others — just like the one time the print head began shimmying everytime you preheated it, making it laborious to load filament, or the present difficulty the place the mattress will typically refuse to warmth up if it’s below a sure temperature.

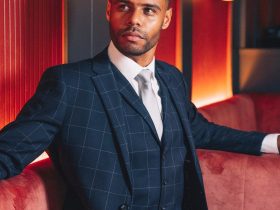

Photograph by Sean Hollister / The Verge

Anker has now had a whole yr to get the AnkerMake M5’s software program proper, but it surely nonetheless seems like a beta. And I’ve a very laborious time recommending a product whose producer is so clearly figuring it out as they go — notably when the corporate’s promoting it like a completed product and speedy rivals have arrived.

It’s one factor in the event you’re catering to an viewers of Kickstarter followers who’re backing your thought at a considerable low cost whereas admitting it wants critical work. It’s one thing solely totally different to promote that product at Amazon, B&H and Finest Purchase, all whereas promising it ought to work superbly and intelligently and robotically shield you from failures, simply fifteen minutes after you open the field.

Replace, 4:21PM ET: Rephrased a line to keep away from confusion; whilst you do want to make use of Anker’s slicer to create the AI picture, you can begin with Gcode from different slicers like Cura and Prusa.