Why it issues: A lot of the present dialog surrounding electrical car manufacturing has centered on sourcing lithium for batteries. Nonetheless, one other crucial part for EVs may come in brief provide within the subsequent few years—electrical metal. Producers within the US are attempting to ramp up manufacturing to compete in a foreign-dominated business.

Analysts estimate that international provides {of electrical} metal—wanted for electrical car motors—may wrestle to satisfy demand earlier than the top of this decade. New firms are coming into the market to keep away from a crunch that might improve EV costs throughout a time once we want them to be extra reasonably priced.

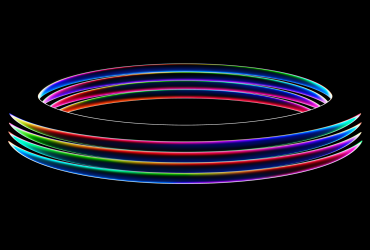

Electrical metal is comprised of ultra-thin sheets that switch electrical energy into mechanical energy. Normal-quality electrical metal varieties the core of the rotating motors powering issues like washing machines, energy transformers, energy instruments, or air conditioners. Electrical car motors and scientific measurement units observe the identical precept however require high-grade electrical metal, which is tougher to supply.

In accordance with a Wall Avenue Journal report, making high-grade electrical metal is an exacting course of, with lead occasions generally approaching an entire yr. It includes stamping and stacking metal and silicon into exact shapes, generally beneath 1 / 4 of a millimeter thick, so firms cannot merely purchase their means into the market.

The overwhelming majority {of electrical} metal at present comes from South Korea, Japan, and China, all of which analysts say are beneath US metal import tariffs. Moreover, international demand for high-quality electrical metal may exceed provide by lots of of hundreds of tons by 2027 and over 1,000,000 tons by 2030.

American firms like Cleveland-Cliffs Inc. and US Metal Corp. are spending thousands and thousands to open new electrical metal mills to assist shut the hole and lift the nation’s competitiveness on this specialised sector. The corporate plans to have a mill up and working by the top of the yr. Nonetheless, it can seemingly take a number of years for home producers to amass the gear and experience to enhance provide considerably. The ensuing state of affairs may put downward stress on EV manufacturing.

The evaluation contrasts with stories of falling costs for different EV uncooked supplies, making the vehicles cheaper within the quick time period. Since January, costs of EV battery elements, like lithium and copper, have fallen by round 20 %. Tesla has handed the financial savings to customers with 5 worth changes this yr. It is unclear how lengthy the state of affairs will final or what is going to occur if it runs into electrical metal shortages.