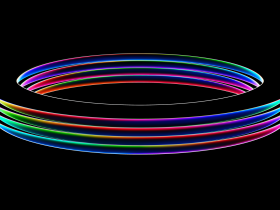

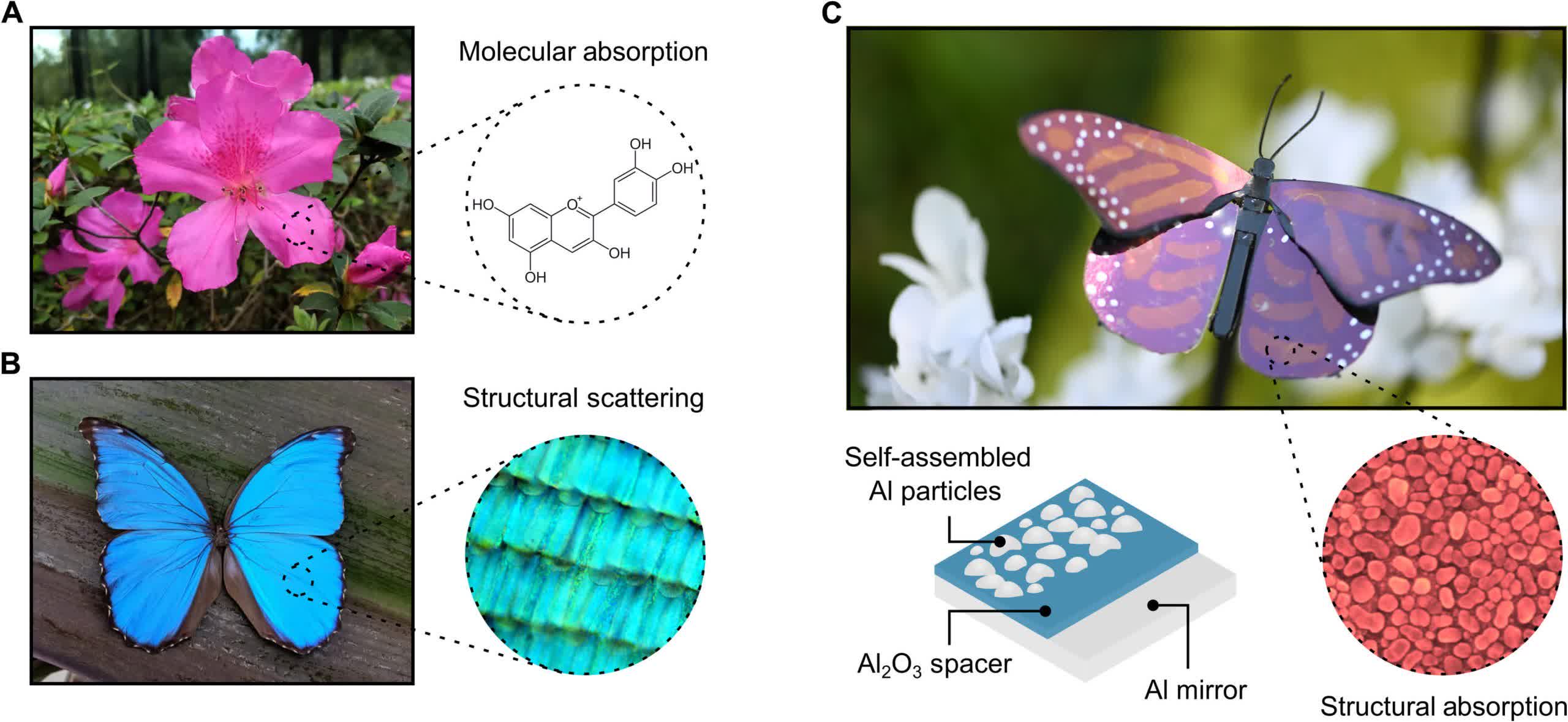

Yeah! Science! Conventional paint is created from a bonding agent, comparable to oil, and pigments from heavy metals like cobalt, ochre, and cadmium, which make blue, crimson, and yellow, respectively. We use paint to paint the substitute world, however in nature, creatures comparable to butterflies and beetles show vibrant palettes with out pigment – they use topography.

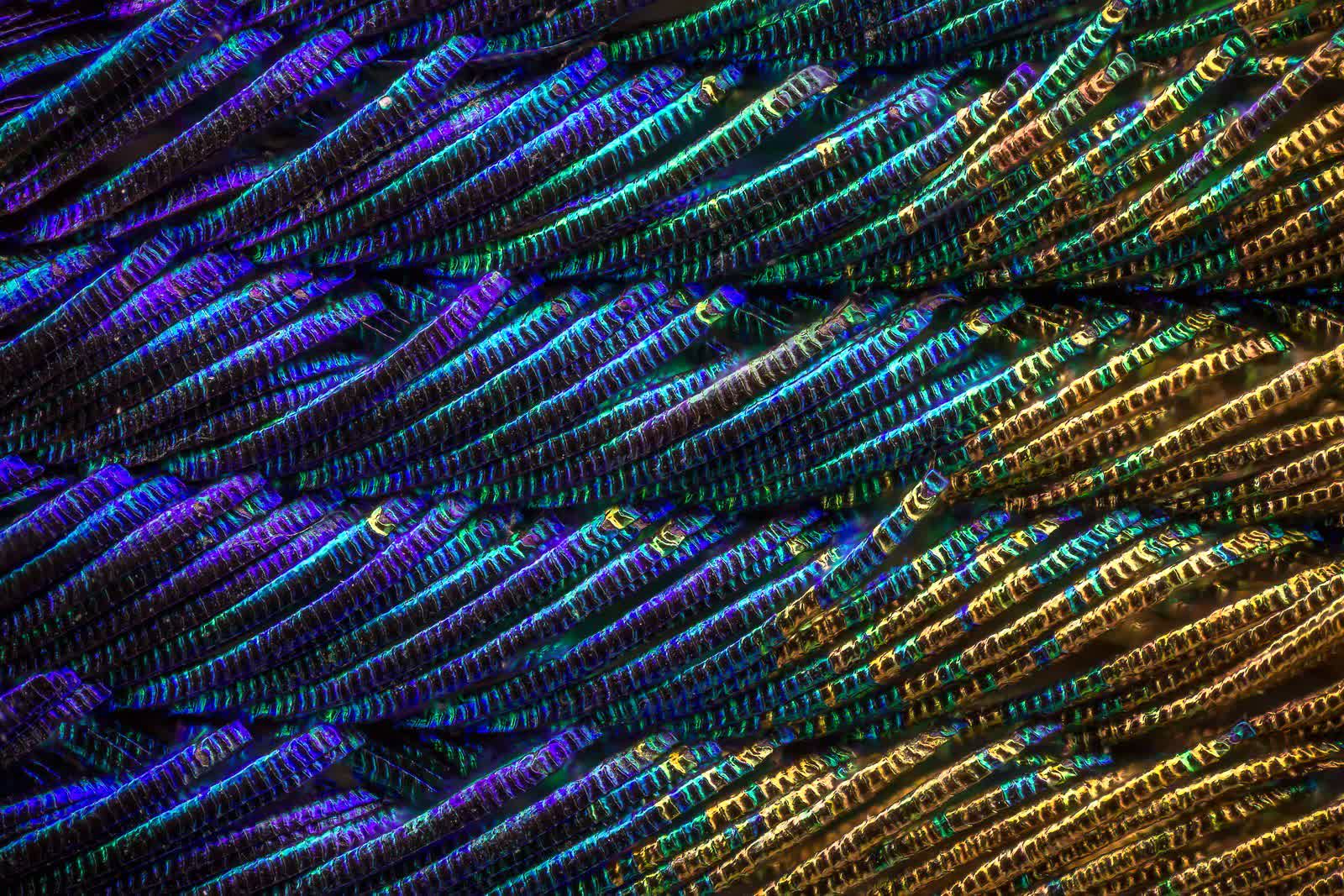

Take a peacock feather, for instance. Submicroscopic ridges and contours in a peacock feather diffract gentle to create the iridescent blues and greens we see. This pure coloring is named structural coloration.

Scientists on the College of Central Florida have developed a “first-of-a-kind” paint that mimics the structural coloring we see in nature. Debashis Chanda, co-author of the research, “Ultralight plasmonic structural coloration paint,” and his crew by chance stumbled upon the invention.

The preliminary purpose was to make an extended steady aluminum mirror utilizing an electron beam evaporator. Nevertheless, after quite a few failed makes an attempt, they observed that the aluminum clumped collectively, creating microscopic “nanoislands.” The bunching prevented the mirror from creating the extremely reflective floor wanted for a mirror. Chanda stated, “It was actually annoying.”

Nevertheless, he observed that the aluminum’s electrons grew to become agitated when ambient gentle hit the nanoparticles, inflicting them to oscillate. Moreover, the electrons resonated with varied wavelengths of sunshine relying on the nanoparticle measurement. White gentle hitting the uneven floor bounced round its ridges earlier than lastly reflecting as a single coloration.

“Simply by shifting the dimension[s of the nanoparticles], you’ll be able to really create all colours,” Chanda instructed Wired.

So the crew started working to create varied colours of paint by rising aluminum nanoislands in a double-sided mirror, then particularly “dissolved” sheets of them into mud the consistency of powdered sugar. They then blended the assorted coloured supplies with binders to make paint.

Chanda stated that due to its structural nature, solely a really skinny coat is required to paint a floor. He says a drop the scale of a raisin can paint either side of a door. This property makes it ultralight, which could possibly be extraordinarily useful within the airline trade.

A Boeing 747 requires about 1,000 kilos of paint. Chanda estimates it might take lower than three kilos of his crew’s structural coloration to coat a jet, shaving over 997 kilos. It may not appear vital for a craft that weighs simply south of 1,000,000 kilos. Nevertheless, simply saving a little bit weight interprets to huge financial savings in gas.

“Provided that gas is already the only largest working expense [about 30 percent last year], airways are all the time thinking about enhancing gas effectivity,” stated a spokesperson for for the Worldwide Airline Commerce Affiliation.

For instance, American Airways estimated that it saved 400,000 gallons of gas and $1.2 million yearly by eradicating solely 67 kilos of pilot manuals from its planes. The corporate claims it saved one other 300,000 gallons in 2021 by switching to a lighter paint that shed 62 kilos from its 737s.

One other benefit of such a paint is its sturdiness. Airways repaint their planes as much as 4 occasions a yr due to the solar’s oxidation results. Structural colours do not fade within the solar, that means repainting is just wanted if you wish to change colours.

One ultimate property of the paint makes it useful in maintaining issues cooler. Most planes are white to mirror as a lot gentle as doable. Absorbed infrared radiation turns into trapped, making the inside hotter.

Preliminary assessments present that the crew’s colorant retains floor temperatures 20-30 levels Fahrenheit cooler than conventional paint, whatever the coloration. It is best for portray planes, vehicles, homes, and different buildings. If it will probably reduce inside temperatures by even 15 levels, it saves huge quantities of vitality used for air con.

The one downside the researchers face now’s scalability. They’ve the gear to make small vials however must produce way more to commercialize realistically. The lab is searching for industrial companions to assist deliver the paint to market.

Picture credit score: United Soybean Board