I’m that man who asks airport safety if I can {photograph} my baggage going by the X-ray machine. I’m additionally the man who spent a stable hour scrubbing by the CT scan of my damaged jaw with a mixture of horror and utter fascination. You may say I’ve been on a little bit of a spectral imaging kick.

So when a startup known as Lumafield instructed me I might put as many issues as I needed into its $54,000 a 12 months radiographic density scanning machine… let’s simply say I’ve a sneaking suspicion they didn’t suppose I’d take it actually.

Final month, I walked into the corporate’s satellite tv for pc workplace in San Francisco with a stuffed-to-the-gills backpack containing:

I might have introduced extra, however I needed to be well mannered!

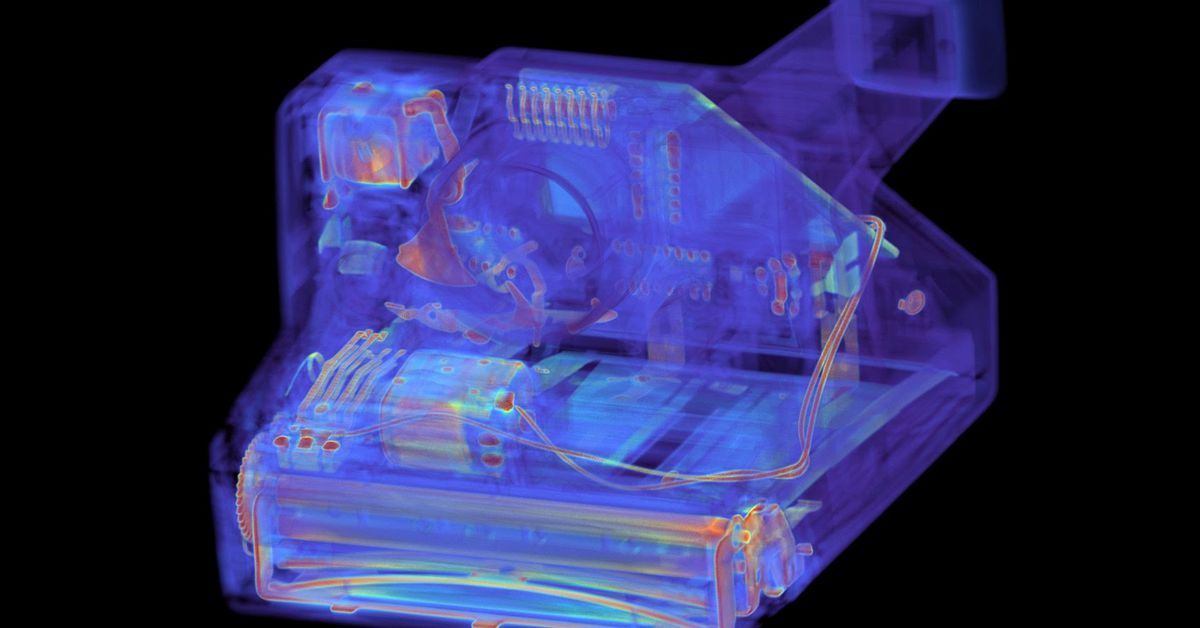

The Neptune, Lumafield’s first scanner, is a hulking machine that appears like a big black microwave oven at first look. It’s six ft large, six ft tall, weighs 2,600 kilos, and a thick sliding steel door guards the scanning chamber whereas the machine is in use. Shut that door and press a button on its built-in touchscreen, and it’ll fireplace as much as 190,000 volts price of X-rays by no matter you place on the rotating pedestal inside.

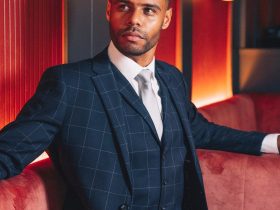

I started with my Polaroid OneStep SX-70, the traditional rainbow-striped digital camera that arguably first introduced on the spot pictures to the plenty. Forty-five minutes and 35 gigabytes of knowledge later, the corporate’s cloud servers turned the Neptune’s rotating radiograms into the closest factor I’ve seen to superhero X-ray imaginative and prescient.

The place my Kaiser Permanente hospital CT scan solely produced ugly black-and-white photos of my jaw that the surgeon needed to interpret earlier than I had the foggiest concept — plus a ghastly low-poly recreation of my cranium that regarded like one thing out of a ’90s online game — these scans appear like the true factor.

In a humble internet browser, I can manipulate ghostly see-through variations of those objects in 3D area. I can peel away their plastic casings, soften them all the way down to the naked steel, and see each gear, wire, chip, and spring. I can digitally slice out a cross part worthy of r/ThingsCutInHalfPorn (word: comprises no precise porn) with out ever selecting up a water jet or noticed. In some circumstances, I can lastly visualize how a gadget works.

However Lumafield isn’t constructing these machines to fulfill our curiosity or to assist reverse engineer. Primarily, it rents them to corporations that must dissect their very own merchandise to verify they don’t fail — corporations that would by no means afford the earlier era of commercial CT scanners.

A decade in the past, Eduardo Torrealba was a prizewinning engineering scholar who’d prototyped, crowdfunded, and shipped a soil moisture sensor that ScottsMiracle-Gro ultimately took off his palms. (Enjoyable truth: his fellow prizewinners have been behind Microsoft’s IllumiRoom and Disney’s Aireal we as soon as featured on The Verge.) Torrealba has been serving to individuals prototype merchandise ever since, each through the Fuse 1 selective laser sintering 3D printer he developed as a director of engineering at Formlabs and as an impartial guide for {hardware} startups after that.

All through, he bumped into points with manufactured elements not turning out correctly, and probably the most compelling answer gave the impression to be a chunk of lab gear: the computed tomography (CT) scanner, which takes a collection of X-ray photos, every of which exhibits one “slice” of an object. Good ones, he says, can value one million {dollars} to purchase and preserve.

So in 2019, he and his co-founders began Lumafield to democratize and popularize the CT scanner by constructing its personal from scratch. It’s now an 80-person firm with $67.5 million in funding and a handful of big-name shoppers together with L’Oréal, Trek Bikes, and Saucony.

“If the one automobiles that existed have been Ferraris, lots much less individuals would have automobiles. But when I’m going to the nook retailer to get a gallon of milk, I don’t want a Ferrari to get there,” he tells The Verge, pitching the Lumafield Neptune as an inexpensive Honda Civic by comparability.

He admits the Neptune has limitations in comparison with a conventional CT, like the way it doesn’t readily scan objects bigger than a motorbike helmet, doesn’t go down to 1 micron in decision, and possibly received’t assist you dive into, say, particular person chips on a circuit board. I discovered it exhausting to establish some digital parts in my scans.

However up to now, Lumafield’s “gallon of milk” is promoting scanners to corporations that don’t want excessive decision — corporations that principally simply need to see why their merchandise fail with out destroying the proof. “Actually, we compete with reducing issues open with a noticed,” says Jon Bruner, Lumafield’s director of selling.

Bruner says that, for many corporations, the state-of-the-art continues to be a band noticed — you actually reduce merchandise in half. However the noticed doesn’t at all times make sense. Some supplies launch poisonous mud or chemical substances while you reduce them. Many batteries go up in flames. And it’s tougher to see how working impacts a working shoe when you’ve added the influence of slicing it in half. “Plastic packaging, batteries, efficiency gear… these are all fields the place we’re changing harmful testing,” Bruner provides.

“We compete with reducing issues open with a noticed”

When L’Oréal discovered the bottle caps for its Garnier cleaning water have been leaking, it turned out {that a} 100-micron dent within the neck of the bottle was guilty, one thing the corporate found in its very first Lumafield scan — however that by no means confirmed up in conventional exams. Bruner says that’s as a result of the earlier methodology is messy: you “immerse in resin, reduce open with a bandsaw, and hope you hit the precise space.”

With a CT scanner, there’s no want to chop: you’ll be able to spin, zoom, and go slice by digital slice to see what’s unsuitable. Lumafield’s internet interface permits you to measure distance with only a couple clicks, and the corporate sells a flaw detection add-on that routinely finds tiny hole areas in an object — often called porosity; it’s on the lookout for pores — which might doubtlessly flip into cracks down the highway.

However solely choose companies like aerospace contractors and main medical system corporations might usually afford such expertise. “Tony Fadell stated [even Apple] didn’t have a CT scanner till they began engaged on the iPod nano,” Bruner relates. (Fadell, creator of the Apple iPod and co-founder of Nest, is an investor in Lumafield.)

Torrealba means that whilst you might possibly discover a primary industrial CT scanner for $250,000 with $50,000 a 12 months in ongoing software program, upkeep, and licensing charges, one equal to the Neptune would run $750,000 to $1 million simply in upfront prices. In the meantime, he says, some shoppers are paying Lumafield simply $54,000 a 12 months ($4,500 a month), although many are extra like $75,000 a 12 months with a few add-ons, resembling a lower-power, higher-resolution scanner or a module that may examine an element in opposition to its unique CAD design. Every scanner ships to your workplace, and the value consists of the software program and repair, limitless scans, and entry for as many workers as you’d like.

How can Lumafield’s CT scanner be that a lot cheaper? “There’s by no means been market stress throughout the trade to push prices down and make it extra accessible,” says Bruner, saying that plane producers, for instance, have solely ever requested for higher-performance machines, no more inexpensive ones, and that’s the place Lumafield finds a possibility.

Torrealba says there are many different causes, too — like how the corporate employed its personal PhDs to design and construct the scanners from scratch, assembling them at their very own amenities in Boston, writing their very own software program stack, and making a cloud-based reconstruction pipeline to chop down on the compute they wanted to place contained in the precise machine.

Even after a pair of interviews, it’s not wholly clear to me simply how profitable Lumafield has been because it emerged from stealth early final 12 months. Torrealba says the workforce has shipped greater than 10 however fewer than 100 machines — and would solely say that the quantity isn’t 11 or 99, both. They wouldn’t point out the names of any shoppers that aren’t already listed on their case research web page.

Picture: Vjeran Pavic / The Verge

However when you take the director of selling at his phrase, Lumafield is making waves. “Within the case of footwear, now we have most of the family names in that area,” says Bruner, including that “a variety of the large family names” within the client packaged items class have signed on as properly. “In batteries, it’s a gaggle of corporations, a few of that are giant and a few small.” Product design consultancies are “a handful of shoppers,” and Lumafield has approached Kickstarter and Indiegogo to gauge curiosity, too.

Lumafield believes it might additionally get enterprise from sectors that really have used CT scanning earlier than — like medical system and auto half producers — largely by being sooner. Whereas most of the high-quality scans of my devices took hours to finish, Bruner says that even these corporations that do have entry to CT scanners may not have them at hand and must mail the half to the precise facility or an impartial scanner bureau. “It’s the distinction between having your engineering drawback answered in two hours and ready per week.”

And for easy injection molded merchandise like some auto elements, Lumafield even retrofitted the Neptune with a totally computerized door, so a robotic arm can swing elements out and in of the machine after a fast go / no go porosity scan that takes properly below a minute to finish. Torrealba says one buyer is “doing one thing adjoining” to the auto half instance, and a couple of buyer is inspecting each single half on their manufacturing line as of immediately.

Automation isn’t what the Neptune was initially supposed for, Torrealba admits, however sufficient prospects appear that he needs to design for high-volume manufacturing sooner or later.

Video: Lumafield: GIF: The Verge

I’ve stored my Polaroid digital camera on my desk the whole time I’ve been typing and enhancing this story, and I can’t assist however decide it up every now and then, remembering what’s on the opposite facet of its black and white plastic shell and imagining the parts at work. It offers me a better appreciation for the engineers who designed it, and it’s intriguing to suppose future engineers would possibly use these scanners to construct and check future merchandise, too.

I’d love to listen to when you spot something significantly cool or uncommon in our Lumafield scans. I’m at sean@theverge.com.